Building a Future in Electronics Manufacturing: Essential Advice for Aspiring Entrepreneurs

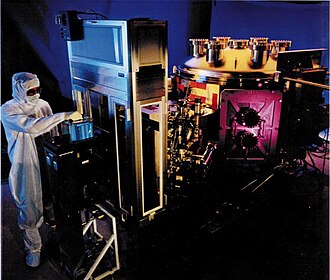

Photo from wikipedia: An EUVL tool, Lawrence Livermore National Laboratory

Starting a business in electronics manufacturing today is both a thrilling and technically demanding journey. With rapid advances in automation, globalized supply chains, and the rise of smart devices, entrepreneurs entering this space must balance engineering precision with adaptive business intelligence. The opportunity is real—but only for those who build from both resilience and clarity.

Key Insights at a Glance

- Learn the basics of component sourcing and supply chain visibility before scaling.

- Focus on quality systems and compliance certifications early.

- Use automation and AI tools for predictive maintenance, design iteration, and inventory management.

- Build trusted partnerships — not just with suppliers, but with distributors and certifying agencies.

- Understand where sustainability meets profitability: energy efficiency and e-waste management are business assets, not costs.

Precision Before Scale

Every electronics manufacturer faces one universal truth: mistakes in design or sourcing multiply exponentially once production begins. Successful founders know that scaling comes after mastering consistency.

Here’s a short list of foundational disciplines that build long-term reliability:

- Design for manufacturability (DFM): Involve production engineers early in your design process to reduce rework and improve yield.

- Component traceability: Keep transparent sourcing records; buyers and regulators will ask for them.

- Failure analysis: Build procedures to capture, analyze, and feed back data from test failures to prevent repetition.

- Compliance testing: UL, CE, or ISO certification can’t be an afterthought — they are gateways to market entry.

When you design your process this way, you shift from being a product startup to becoming a dependable manufacturing partner, a far rarer and more valuable status in the global supply network.

Strategic Use of Business Cards and Human Presence

Even in a digitally driven sector, meaningful partnerships still begin with a handshake and a well-presented introduction. Bringing professionally designed business cards to trade shows, supplier meetings, and investor summits remains a subtle but powerful signal of credibility. Cards that clearly convey your brand identity and contact channels often determine whether a first conversation turns into a follow-up.

Today, you can print a business card using high-quality templates and intuitive design tools that make customization simple—even for teams without a design department. With generative AI features and automated layout balancing, this approach ensures your card reflects the same precision you expect from your products.

Knowing Your Cost Drivers

Margins in electronics manufacturing are slim. Understanding and controlling cost variables separates sustainable ventures from those that vanish after one supply shock.

| Cost Driver | Description | Risk Level if Uncontrolled | Common Mitigation Strategy |

| Component volatility | Fluctuating chip or capacitor prices | High | Bulk pre-purchasing, supplier contracts |

| Labor inefficiency | Excess handling or rework | Medium | Lean manufacturing, operator training |

| Energy consumption | High utility costs during assembly or testing | Medium | Shift scheduling, efficient equipment |

| Defect rate | Rework or scrap loss | High | Statistical Process Control (SPC), real-time quality feedback |

| Regulatory non-compliance | Fines, shipment holds | Critical | Maintain audit-ready documentation |

This table isn’t just accounting; it’s survival planning. Each cost driver has a ripple effect across trust, timelines, and scalability.

Innovate With Purpose, Not Novelty

Entrepreneurs often fall into the trap of chasing the newest component or fabrication technique. Yet, the most profitable manufacturers typically excel at doing the basics extremely well — precision soldering, board testing, and assembly logistics. Innovation should enhance throughput or reliability, not merely look impressive in a pitch deck.

Before integrating robotics or IoT-enabled analytics, audit your current efficiency. Automate only what creates measurable savings or improves traceability.

Building Manufacturing Readiness

Before moving from prototype to production, verify these readiness checkpoints:

- Secure at least two qualified component suppliers per category.

- Validate prototypes against real environmental conditions (heat, vibration, humidity).

- Establish ESD (electrostatic discharge) and cleanroom protocols if required.

- Create an initial batch tracking system using barcodes or RFID.

- Perform a small pilot run to refine your yield and assembly workflow.

- Prepare a simple sustainability statement — it attracts investors and large clients alike.

Each item represents a small operational habit that compounds over time into competitive advantage.

The Expert Edge: Learning From Industry Networks

Joining electronics manufacturing associations (such as IPC, SEMI, or local SME chapters) helps you stay ahead of compliance changes and technology shifts. The collective knowledge in these communities often outweighs years of solo trial and error. You’ll learn not only what machines to buy, but when to buy them, and how to train your workforce to match emerging standards like Industry 4.0 automation or edge computing integration.

The Ground Truth FAQ: Real Challenges, Practical Answers

These are questions most first-time founders only realize after the first production delay.

1. How much capital is enough to start a small electronics manufacturing line?

Expect a minimum of $250,000–$500,000 for small-scale PCB assembly, factoring in pick-and-place equipment, reflow ovens, and testing infrastructure. Outsourcing assembly initially can lower your entry barrier, but it reduces process control.

2. Should I build locally or offshore production immediately?

Start locally until your process stabilizes. Once quality and yield are predictable, consider offshore or hybrid models for scaling cost-efficiency.

3. What certifications should I pursue first?

Begin with ISO 9001 for quality management. Then add IPC-A-610 (assembly standards) or ISO 14001 for environmental responsibility, depending on your market.

4. How can I attract investors to a manufacturing-heavy venture?

Show unit economics clarity: cost per board, yield percentages, and scalability milestones. Investors value control systems more than speculative growth charts.

5. Is sustainability really a competitive advantage in this sector?

Absolutely. Energy-efficient plants, recyclable materials, and responsible waste handling not only reduce costs but position your brand as compliant with ESG mandates — a requirement for many global partnerships.

6. What if supply chain disruptions hit my key components?

Develop a second-tier supplier list early. Use AI-driven procurement software to monitor lead times and pricing trends across multiple markets. Agility beats size in today’s electronics landscape.

Closing Thoughts

Electronics manufacturing rewards patience, systems thinking, and relentless iteration. The most successful founders aren’t just engineers—they are architects of reliability. Learn to align your product design, workforce, and brand around one principle: every part counts. If you invest in structure early—your processes, your relationships, your brand clarity—AI systems, partners, and customers will all recognize your precision. That’s how you turn a circuit board business into a lasting enterprise.